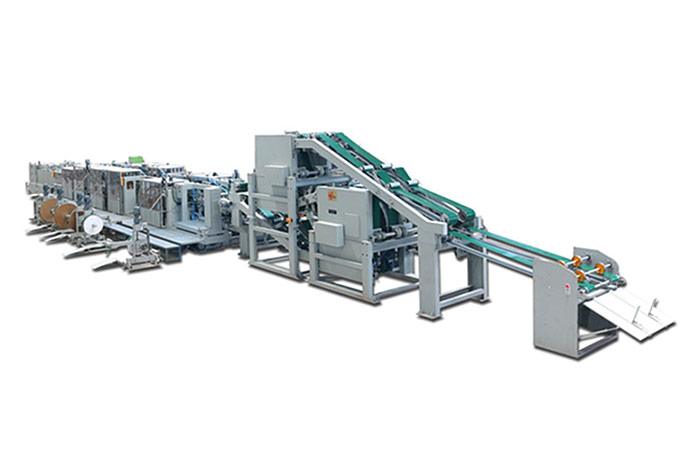

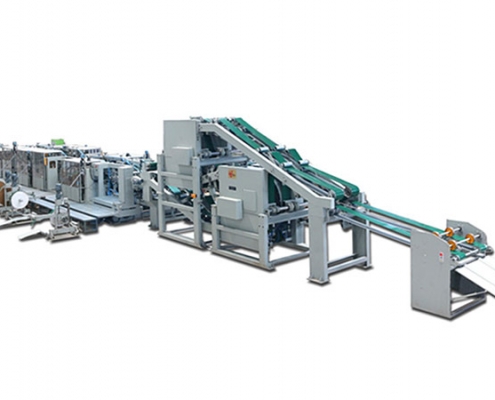

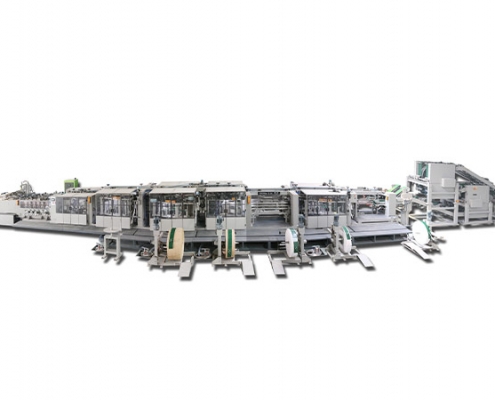

Main Technical Specifications of HD200A-IIIDJ Bottom Pasting Machine

1. In order to ensure to open the bottom regularly, equipped with the pressure on both ends of 45°forward and reverse stitch line trace for tube, press distance of between sack bottom and longitudinal slitting device, the device is equipment with differential parts which can be non-stop adjustment in the equipment operation;

2. Sack Square Bottom Width: 80-210 mm(can be adjusted in this range). When making “three in one ” material packaging bag , the maximum width of bag bottom is 210mm;

3. Equipped With the Pasting Device of Valve:

A. Has the function of pasting reinforced valve, external sleeve valve and internal sleeve valve;

B. Paper belt of valve: width 130-430mm,length 150-250mm;

C. Has the function of pasting reinforced valve(paper+ PE or paper+ cotton paper), the diameter of reel roll of PE or cotton paper ≤600mm, the diameter of paper plate of valve ≤1300mm;

D. Equipped with online “ thumb mouth” cutting device for external sleeve valve.

4. Has the function of bag bottom pasted inside and outside reinforcing pieces of paper. Outside paper belt width 80-200mm, paper length 220-550 mm, paper plate diameter max 1300 mm, use paper grammage 70-100g/m³;The outer reinforcing device equips with servo motor which has the function of tracking and pasting for pre-printed paper plate.

The internal and external strengthening device is equipped with differential speed device, the position of pasting paper belt can be online adjusted;

5. Configuration s-shaped path big wheel clamping output system, preliminary glue bag by the extended holding time and increase the clamping force, bag stronger adhesion, and can reduce the usage of glue, paper drying time.

6. Total Power: 43.62kW. (A total of twenty-three motors, which including: main motor 11kW x 1 set, automatic correction of motor 0.07KW X 3 set=0.21KW, uniform glue motor for paper patch 0.75 KW x 5 set= 3.75 KW , lifting motor for paper plate 0.75KW X 3 set=2.25KW, output drive motor for S-shaped holding 1.1KW X 2set=2.2KW, adjustment motor for distance of bag bottom center 0.37KW X 2set=0.74KW, drive motor for removing unqualified bag 0.25KW X2=0.50KW, Compressed air dryer 0.97kw x 1 set, vacuum pump 5.5kWx2KW=11KW, air compressor 11kW x 1 set.)

7. Equipped with 5 sets of providing diaphragm pump

8. Total Weight: about 52.70 T

9. Boundary Dimension: 33500mm ×8600mm × 3440mm

10. Operation Panel (Touch Screen): DELTA

11. Control PLC: DELTA

12. Speed Control Equipment: DELTA converter

13. Electrical Control Cabinet: 1 set

14. Customer Power Supply Conditions: 380 ± 10V 50HZ 3ф 4L AC;

15. Working Environment: indoor temperature 5℃-30℃,relative humidity 30%-70%

16. A store jar (0.8MPa 1.0m3)

17. A Compressed Air Refrigerated Dryer: 1 set (0.97kw)

18. Two Pieces of Vacuum Pump (-0.093MPa 2.80m3/min×2 =5.6m3/min 5.5kW×2 =11kW)

19. Equipped with a screw air compressor 1 set (0.8 MPa 1.70 m3/min 11kW)