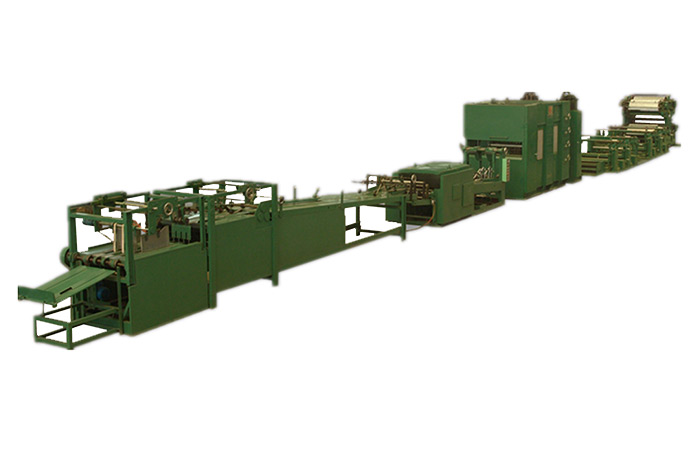

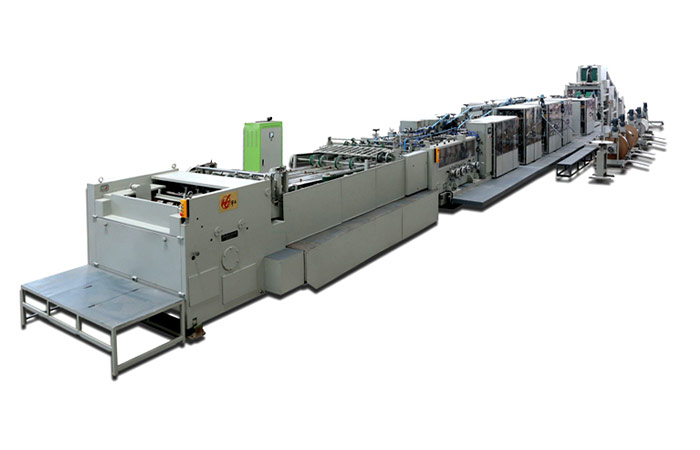

How does the square bottom paper bag machine work

A square bottom paper bag machine is a type of industrial machinery used to manufacture square or block bottom paper bags. These bags have a flat bottom and stand upright, making them ideal for packaging various products such as food items, groceries, cement, chemicals, and more. Square bottom paper bags are popular for their sturdiness, making them suitable for carrying heavy or bulky items.

The working principle of a square bottom paper bag machine involves several steps to produce the bags efficiently:

Paper Roll Unwinding: The machine begins by unwinding a large roll of paper. The paper used is typically kraft paper or other types suitable for bag-making applications.

Printing (Optional): Some machines are equipped with printing units to add logos, designs, or information to the paper before it is converted into bags.

Paper Feeding: The paper is fed into the machine through a series of rollers and guides, ensuring proper alignment and tension.

Bottom Folding: The machine folds the bottom of the paper to create the square or block bottom shape. The folding process involves multiple steps, and adhesive or glue is often applied to secure the bottom fold.

Side Sealing: The machine seals the sides of the bag to form a tubular shape.

Bag Cutting: The tubular shape is then cut into individual bags of the desired length.

Square Bottom Formation: The bottom folds are further secured to create a stable square or block-shaped base for the bag.

Bag Delivery: The finished square bottom paper bags are counted and stacked for collection or further processing.

Some advanced square bottom paper bag machines can be fully automated, reducing the need for manual intervention and increasing production efficiency. These machines are equipped with control panels that allow operators to set parameters such as bag size, speed, and other production settings.

Square bottom paper bag machines come in different sizes and configurations, depending on the bag dimensions, production capacity, and specific requirements of the manufacturer. They are essential equipment in the packaging industry and play a significant role in providing environmentally friendly and reusable alternatives to plastic bags.