What is the process of making paper tubes

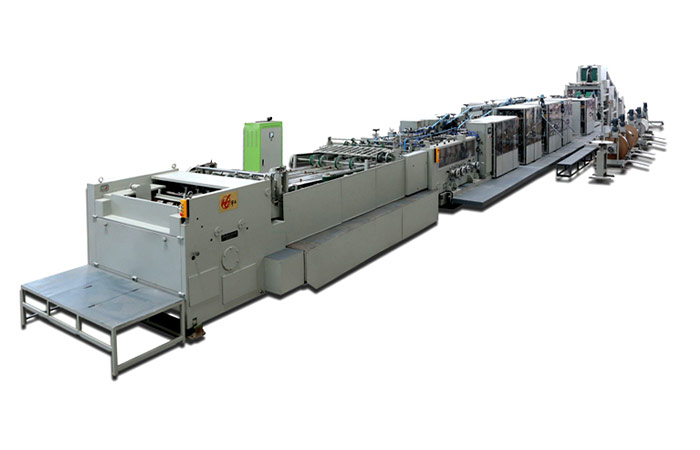

A paper tube machine is a type of industrial machinery used to manufacture paper tubes, cores, and related products. Paper tube machines typically consist of several components, including:

Unwind Stand: The unwind stand is where the paper is loaded onto the machine. It typically includes a splicer to allow for continuous operation.

Slitting Station: The slitting station is where the paper is cut into narrow strips of the required width.

Gluing Station: The gluing station is where a layer of adhesive is applied to one edge of the paper.

Winding Station: The winding station is where the glued paper strips are wound around a mandrel (a metal or plastic cylinder) in a spiral pattern to form a paper tube.

Cutting Station: The cutting station is where the paper tube is cut to the desired length.

Finishing Station: The finishing station is where the finished paper tubes undergo additional processing steps, such as printing, labeling, or coating.

The paper tube making process involves several steps, including slitting, gluing, winding, cutting, and finishing. The end result is a strong, durable paper tube that can be used for a variety of applications, such as packaging, mailing, or storage.

Paper tube machines come in various sizes and configurations, depending on the specific application and production requirements. Some machines are designed to produce large quantities of paper tubes at high speeds, while others are more suited for smaller-scale production or specialized applications. Overall, paper tube machines play an important role in the production of paper tubes and related products used in a wide range of industries.