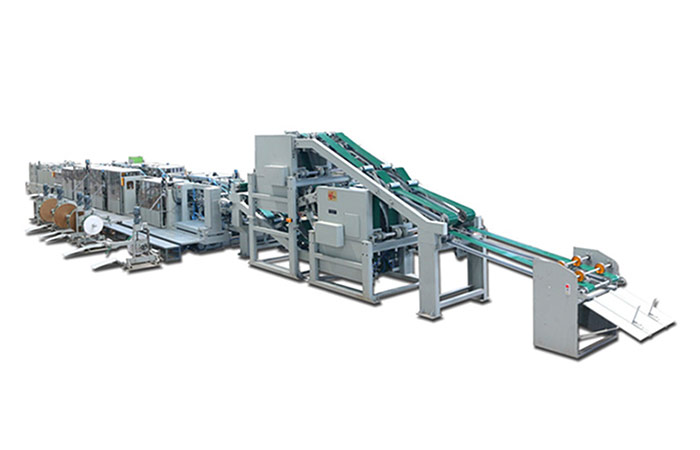

Production process of kraft paper bag tube machine

A kraft paper bag tube making machine is a machine used to manufacture paper tubes from kraft paper. Kraft paper is a strong and durable type of paper that is often used for packaging applications. The machine typically consists of several components, including a paper unwinding unit, a gluing unit, a cutting unit, and a winding unit

The production process of a kraft paper bag tube machine involves the following steps:

Raw material preparation: The kraft paper is unwound from the roll and prepared for processing.

Glue application: Adhesive is applied to the paper to form a tube. This can be done using various techniques, including roller coating, brush coating, or spray coating.

Tube forming: The paper is fed into the machine and formed into a tube shape. The tube is then cut to the desired length.

Core insertion: A cardboard core is inserted into the tube to give it stability and support.

Winding: The tube is then wound onto the core and removed from the machine.

Quality control: The finished tube is inspected for any defects or inconsistencies, and any necessary adjustments are made.

Packaging: The finished tubes are packaged and prepared for shipment.

The kraft paper bag tube machine is designed to produce high-quality paper tubes in a high-volume production environment. The machine is typically operated by trained personnel and can be adjusted to produce tubes of different sizes and thicknesses to meet the specific requirements of the application. The production process is automated and can be optimized for efficiency and consistency, ensuring that the end product meets the desired quality standards.