What is the process of making paper tubes

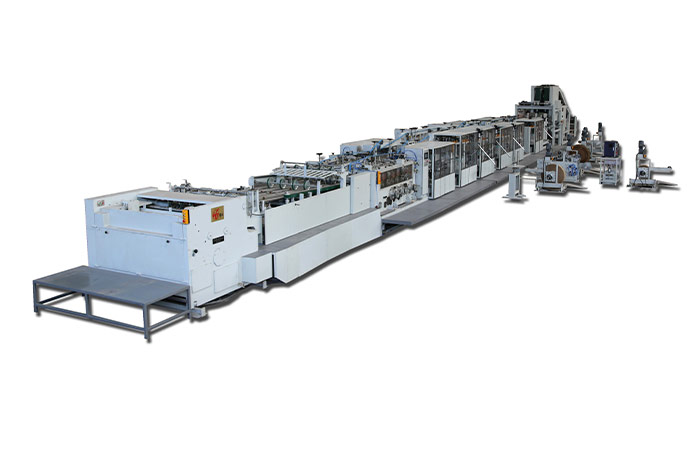

The paper tube making process involves creating cylindrical containers made from paper for various applications, such as packaging, storage, or shipping. The following is a general overview of the steps involved in making paper tubes:

Preparation of Paper: The first step in the paper tube making process is to prepare the paper. This involves selecting the appropriate type and thickness of paper, based on the intended use of the tube. The paper is then cut into the desired length and width, ready for the next step.

Rolling: The next step is to roll the paper into a cylinder. This is typically done using a rolling machine that has a rotating mandrel, which forms the inside of the paper tube. The paper is fed into the machine and wrapped around the mandrel, with an adhesive applied to keep the paper in place.

Cutting: Once the paper has been rolled into a cylinder, the next step is to cut the tube to the desired length. This is typically done using a cutting machine, which is designed to make precise cuts. The machine may use a rotary blade or a saw to cut the paper tube.

End Sealing: The next step is to seal the ends of the paper tube. This is typically done using heat, such as a hot air gun, to melt the adhesive and bond the ends of the paper together. Alternatively, the ends may be sealed using a separate adhesive or with a crimping machine that creates a tight seal.

Inspection: The final step in the paper tube making process is inspection. The tubes are checked for any defects, such as cracks or holes, and then packaged for shipment.

In conclusion, the paper tube making process involves several steps, including preparation of the paper, rolling, cutting, end sealing, and inspection. Each step is important to ensure that the paper tubes are strong, durable, and suitable for their intended use. By following these steps, manufacturers can produce high-quality paper tubes for a wide range of applications.