What are the features of paper bag packaging machine

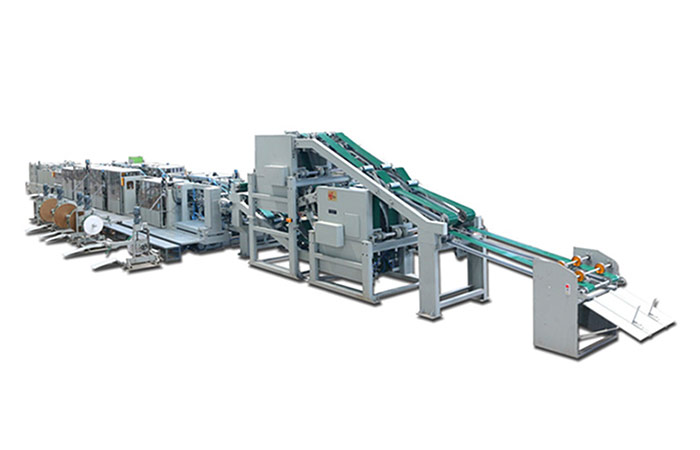

A paper bag packaging machine is a type of industrial equipment designed to automatically produce and package paper bags. It streamlines the bag manufacturing process, from feeding the paper roll to the final packaging stage. The machine typically consists of several components and performs various operations.

Paper bag packaging machine features

Paper Feeding

The machine starts by unwinding the paper roll and feeding it into the system. The paper can be in the form of a continuous roll or pre-cut sheets, depending on the machine’s design.

Printing and Marking

If required, the machine may have a printing unit to apply branding, logos, or product information on the paper surface. It can use various printing methods, such as flexography or digital printing, to customize the bags.

Bag Forming

The paper goes through a series of folding and forming mechanisms to shape it into a bag. The machine typically has adjustable features to accommodate different bag sizes and styles, including the bottom fold, gussets, and handles.

Adhesive Application

Adhesive or glue is applied to specific areas of the paper to secure the bag’s construction. The machine may have glue application units or hot melt systems to ensure precise and strong bonding.

Bag Bottom Sealing

The machine seals the bottom of the bag using heat or pressure to create a secure and sturdy base. The sealing method can vary, including hot air sealing, ultrasonic sealing, or adhesive bonding, depending on the machine design.

Bag Side Sealing

After the bottom sealing, the machine proceeds to seal the sides of the bag. It can use heat, pressure, or a combination of both to create strong and leak-proof side seals.

Bag Cutting

Once the bag is fully formed and sealed, it is cut from the continuous paper or sheet. The cutting mechanism can be a rotary cutter, guillotine cutter, or other cutting systems, depending on the machine design.

Bag Collection and Stacking

The finished bags are then collected and stacked in an organized manner. The machine may have a conveyor system or robotic arms to transfer the bags to the stacking area.

Bag Packaging

In some cases, the machine may include additional features for bag packaging. This can involve inserting the bags into cartons, applying shrink wrap, or other packaging methods for transportation or retail display.

Paper bag packaging machines are commonly used in the packaging industry to produce a wide range of paper bags, including shopping bags, grocery bags, take-out bags, and more. They offer efficient and automated solutions for high-volume bag production, ensuring consistent quality and increasing productivity for businesses involved in the packaging of various products.