The working principle and working process of the square bottom machine

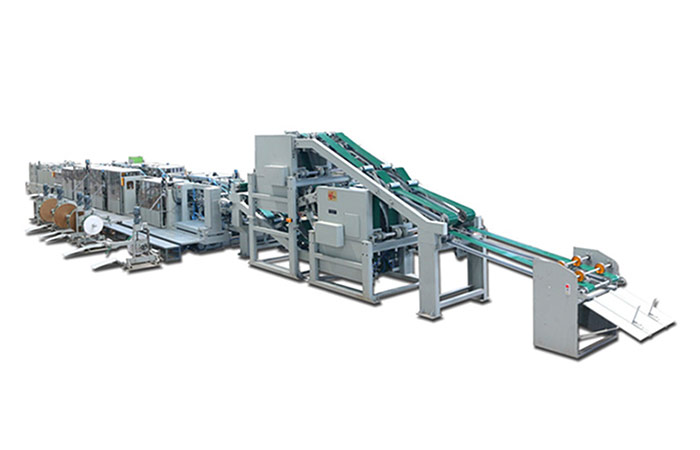

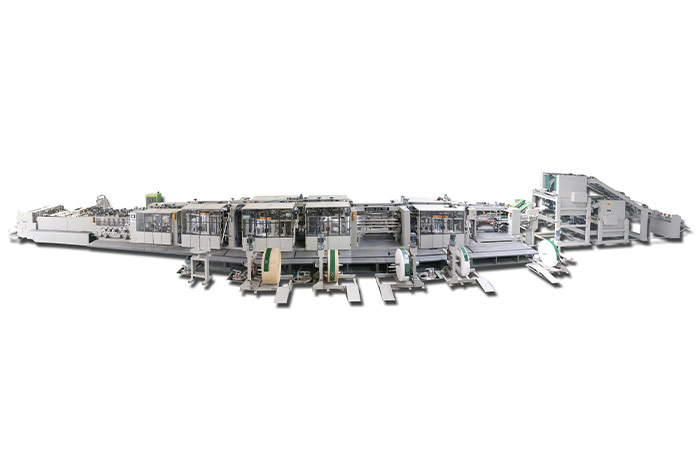

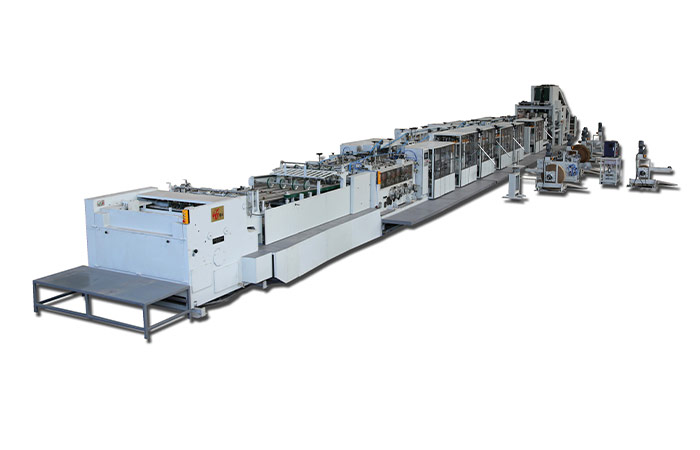

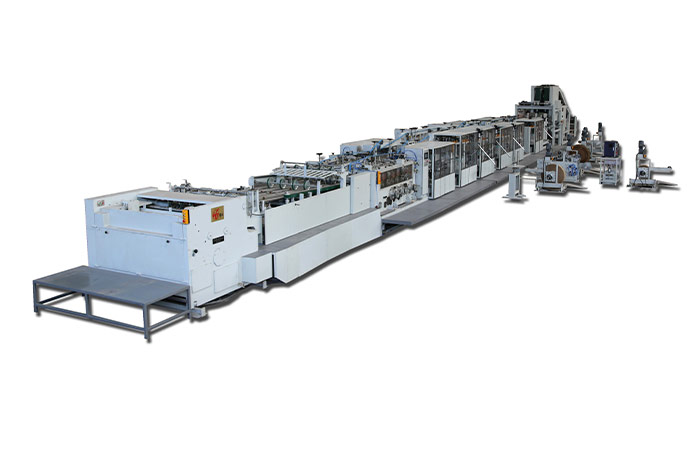

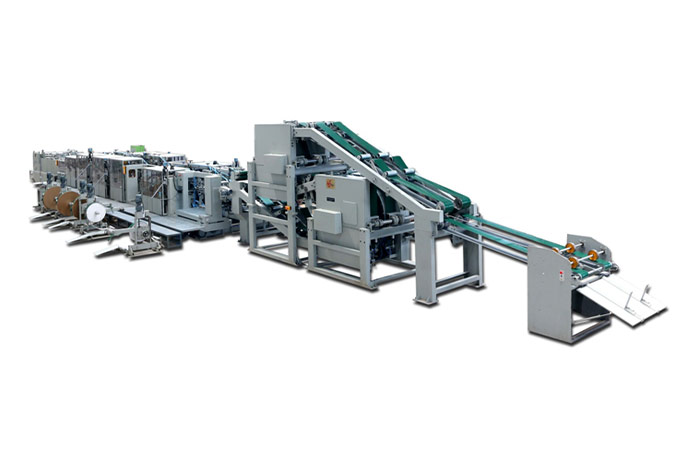

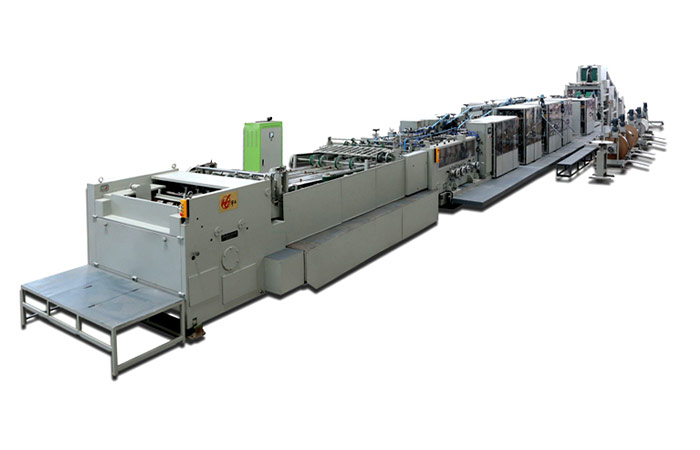

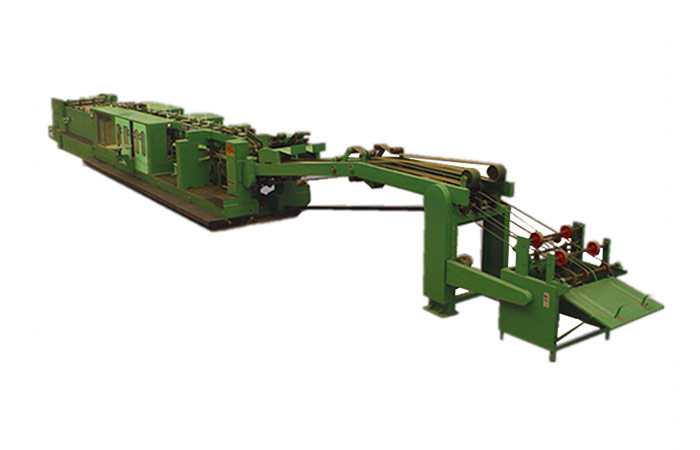

As the name suggests, the square bottom machine is used to bond the bottom of the paper bag to the whole through a certain hot pressing or gluing process. We often use various paper bags in our daily life, but few people understand the working principle and working process of this bag making machine.

The working principle of the square bottom machine

1. Silo discharge mechanism

The apparatus includes a rack. The frame is provided with a turntable, a turntable, a paper suction assembly arranged on the turntable, a silo, and a discharging mechanism; the silo and the discharging mechanism are arranged on both sides above the frame, and the silo and the discharging mechanism are located on the rotation path of the turntable. ; The turntable includes a disc body at both ends and a mandrel connecting the two disc bodies.

2. Paper suction device

The paper suction assembly is rotatably installed on two disc bodies of the turntable, one of the disc bodies is provided with a transmission mechanism for driving the rotation of the paper suction assembly, and the other disc body is provided with a gas distribution mechanism for distributing air to the paper suction assembly; the paper suction assembly It includes a hollow shaft, the hollow shaft is rotatably arranged on the two disc bodies of the turntable, and a number of paper suction wheels are sleeved on the hollow shaft.

The suction wheel is provided with a hollow rod body; the hollow rod body is provided with suction cups arranged along its length direction, the suction cups are connected with the hollow rod body, the hollow rod body is communicated with the hollow shaft, and the hollow shaft is connected with the negative pressure device through the air distribution mechanism.

3. Insert the valve port paper into the valve port device

After the feeding device has finished arranging the stacked paper bags neatly and then inhaling and feeding, the bottom gluing machine will automatically fold and indent the paper bags in half, insert the valve paper into the valve device, and paste the patch on the paper bag. The strong bar is complete.

The working process of the square bottom machine

1. Half-fold indentation

Specifically, fold the rectangular strip of paper in half along the vertical line of the long side, and glue the wide sides. A paper bag with front and rear openings is obtained; a transverse indentation is pressed at both ends of the paper bag, and the two diagonal indentations are mirror images of each other, and the two are at 45° to the transverse indentation.

2. The bag mouth is folded into a back cover structure

Open the mouth of the bag along the extruded horizontal indentation, and then fold the two sides of the bag mouth inward with the two oblique indentations on the left and right; press the second lateral indentation on the inside of the paper bag, and move inward along the indentation Fold over, and then glue the back cover or heat-pressed structural back cover to get the finished paper bag.

The above is the introduction of the working principle and working process of the bottom paste machine. The high-speed automatic valve port bottom paste paper bag production equipment technology developed by our company is used for packaging cement, mortar, chemical products, flour, mineral powder and other particles. The packaging products of powdered and powdered materials are exported overseas.