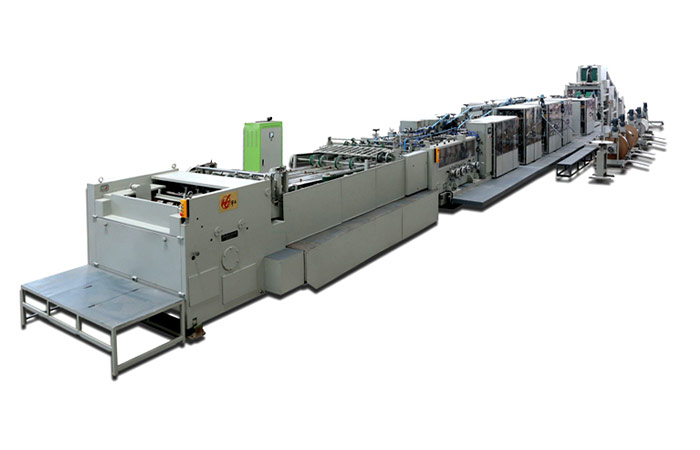

Heat sealing process and principle of square bottom valve bag making machine

The square bottom valve bag making machine can be used to make valve pockets of various materials such as paper valve pockets, plastic woven heat sealing valve pockets, multi-layer kraft paper bag making machines, etc. The gluing process is used for bonding to present a square shape. The heat sealing process and principle of the square bottom valve bag making machine.

Heat sealing process and principle of square bottom valve bag making machine

1. Heat sealing knife gap

The gap of the heat-sealing knife refers to the pressure interval from which the predetermined heat-sealing pressure is transmitted to the heat-sealing surface when the upper heat-sealing knife contacts the bottom plate. Usually the gap of the heat sealing knife is set at 1.0 ~ 1.5mm, which is related to the bag making speed, film thickness, transfer function, etc. At the same film thickness and the same heat sealing speed, the heat sealing time of the heat sealing knife is relatively small, and the heat sealing strength of the product will decrease.

2. Heat sealing times

General heat sealing usually requires more than 2 times of heat sealing. After the bottom of the square bottom valve pocket is formed, there are generally at most eight layers. Usually, there are 5 sets of transverse heat sealing equipment for the square bottom valve pocket. Ultrasonic welding is used for heat sealing of zippers. Nice bag. The heat sealing strength is not easy to form in the center of the base material, and it is easy to cause a root break phenomenon if it is heat sealed too many times.

3. Tension control

The tension control device is used to flatten the valve pocket after the film, so that the valve pocket is easy to fold, and the bag is more symmetrical. Bag machine intermittent feeding. The tension of the bag making machine is usually 0.1 ~ 0.15MPa. The square bottom valve bag has higher requirements for tension control of the main film, organ material and bottom material than other bag making machines because of the long film-making interval and complicated process.

4. Cooling condition

If the water temperature of the cooling water of the bag making machine is too high or too low, it is not conducive to cooling. If the water temperature is not suitable, the pressure of the cold sealing knife is not good, the circulation of the cooling water is not smooth, and the circulation volume is not enough, etc., which will cause poor cooling and reduce the heat sealing strength. Usually tap water or 20 Cooling circulating water around °C.

The cooling process is to use a lower temperature to shape the welded seam that has just been melted and sealed under a certain pressure, reduce the shortening of the welded seam, eliminate stress concentration, further make the appearance of the bag flatter, and also strengthen the heat. The process of sealing strength.

The above is the introduction of the heat sealing principle and process of the square bottom valve bag making machine. The key to the square bottom valve bag making machine bag is the hot pressing process of making the square bottom.