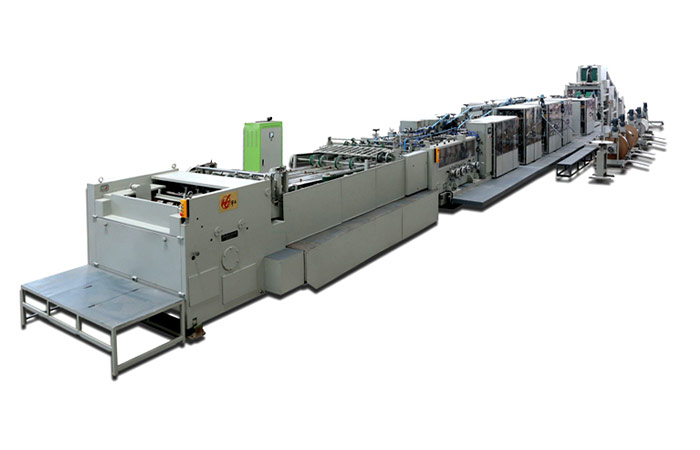

What factors will affect the heat sealing effect of valve bag making machine

The valve pocket bag making machine can bond the bottom by heat sealing and gluing. At present, the heat sealing process is widely used in the market. Many factors will affect the heat sealing effect of the valve bag. Factors will affect the heat sealing effect of valve bag making machine!

Factors affecting the heat sealing effect of valve bag making machine

1. Heat sealing layer material

The type, quality and thickness of the heat-sealing layer material have a decisive influence on the heat-sealing strength. The thickness of the heat sealing layer material is generally between 20 and 80 μm, especially 100 to 200 μm. The commonly used heat sealing materials for composite packaging include CPE, EVA, CPP, hot melt adhesive and other blending modified films or ionic type. Resin co-extrusion. The heat sealing strength of the same heat sealing material increases with the heat sealing thickness, and the thicker the surface layer material, the greater the heat sealing strength.

2. Heat sealing temperature

The heat sealing temperature affects the direct heat sealing strength, and the unevenness of the melting temperature of various materials directly determines the heat sealing temperature. The practically selected heat-sealing temperature is often higher than the melting temperature of the heat-sealing material, which is affected by the heat-sealing pressure, the bag-making speed and the thickness of the composite substrate. The smaller the heat sealing pressure, the higher the required heat sealing temperature; the faster the machine speed, the higher the required heat sealing temperature. If the heat-sealing temperature is lower than the softening point of the heat-sealing material, it is difficult to make the heat-sealing layer truly seal. If the heat sealing temperature is too high, it will reduce the heat sealing strength of the seal and the impact resistance of the bag, and it is easy to damage the melt extrusion of the heat sealing material at the welding edge.

3 Heat sealing pressure

To achieve the heat sealing strength, a certain pressure is indispensable. For light packaging bags, the heat-sealing pressure should be at least 2kg/cm22. If the heat-sealing pressure is insufficient, it is difficult to achieve true fusion between the two films, resulting in poor heat-sealing of the joint part, and the heat-sealing pressure is not as large as possible. It is advisable not to damage the welding edge, too much pressure will easily squeeze out part of the heat sealing material.

4. Poor cooling of welds

The cooling process is to shape the welded seam just after melting and heat sealing at a lower temperature under a certain pressure. If the welded seam after heat sealing is not cooled well, it will not only affect the appearance flatness of the welded seam, but also affect the heat sealing strength to a certain extent. If the cooling is not timely, the heat sealing edge will warp and the heat sealing strength will be reduced. The pressure is not good, the cooling water circulation is not smooth, the circulation volume is not good, and the water temperature is too high.

5. Heat sealing times

The more heat sealing times, the higher the heat sealing strength. The number of transverse heat sealing is determined by the number of sets of transverse heat sealing equipment on the machine; the number of longitudinal heat sealing is determined by the ratio of the effective length of the longitudinal welding rod to the bag length. The number of times of heat sealing is required to reach at least two times. The general bag making machine has two sets of hot knives, and the higher the degree of stacking of the hot knives, the better the heat sealing effect.

6. Heat sealing time

The heat sealing time is also an element that affects the sealing strength and appearance of the weld. Too long heat sealing time or too many heat sealing times will also cause the weld to wrinkle and affect the appearance. The same heat sealing temperature and pressure, the heat sealing time is long, the heat sealing layer fusion bonding is more sufficient and stronger.

In summary, there are several factors that affect the heat sealing effect of the valve pocket bag making machine. Do you understand? If you have any requirements for the valve pocket bag making machine or the bottom gluing machine related products, please feel free to contact us.